Unlocking the Power of Forklift Quick Release Mounting Hooks

In the fast-paced world of industrial operations, efficiency and safety are paramount. forklift quick release mounting hooks Every second counts, and every maneuver should be as smooth as possible. This is where forklift quick release mounting hooks come into play, revolutionizing the way materials are handled and transported. Let’s delve into the world of these ingenious devices and discover how they can enhance productivity and safety in various settings.

Understanding Forklift Quick Release Mounting Hooks

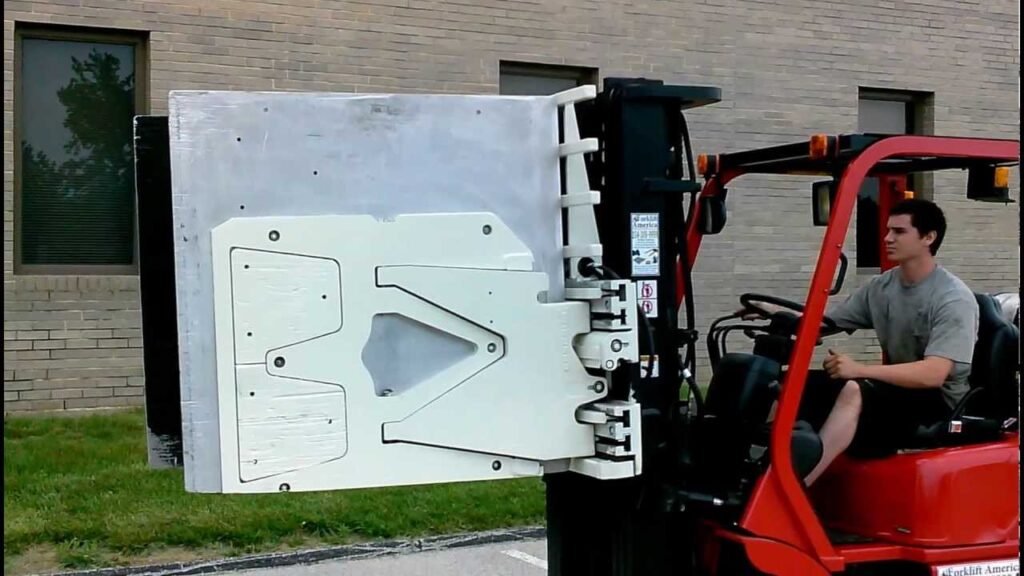

Forklift quick release mounting hooks are ingenious attachments designed to facilitate the swift and secure handling of loads by forklifts. They provide a hassle-free solution for attaching and detaching various implements, such as buckets, pallet forks, or clamps, to the forklift’s carriage. Essentially, they act as the bridge between the forklift and the load, ensuring a seamless connection.

How Do Forklift Quick Release Mounting Hooks Work?

Imagine them as the universal keys of the forklift world. Just like how a key effortlessly unlocks a door, these hooks allow operators to swiftly attach and detach implements without the need for manual labor or complex mechanisms. They typically feature a simple yet robust design, enabling operators to change attachments within seconds, thereby minimizing downtime and maximizing efficiency.

Benefits of Using Forklift Quick Release Mounting Hooks

Streamlined Operations: With these hooks, switching between different attachments becomes a breeze, allowing forklift operators to adapt quickly to changing tasks and environments.

Time Efficiency: Say goodbye to the tedious process of manually securing attachments. These hooks enable rapid changes, saving valuable time during operations.

Enhanced Safety: By eliminating the need for manual intervention in attachment changes, the risk of accidents and injuries is significantly reduced, promoting a safer work environment.

Versatility: Whether you’re handling pallets, barrels, or specialized equipment, forklift quick release mounting hooks offer compatibility with a wide range of implements, enhancing the versatility of your forklift.

Applications in Different Industries

From warehouses to construction sites, these hooks find applications in various industries where the efficient handling of materials is crucial. They’re indispensable tools in logistics, manufacturing, agriculture, and beyond, providing unparalleled convenience and flexibility in material handling operations.

Choosing the Right Forklift Quick Release Mounting Hooks

When selecting these hooks for your forklift, consider factors such as load capacity, compatibility with existing attachments, and durability. Opt for reputable manufacturers known for producing high-quality, reliable products that meet industry standards and regulations.

Maintenance Tips for Longevity

To ensure optimal performance and longevity of your forklift quick release mounting hooks, regular maintenance is key. Keep them clean, lubricated, and free from debris or damage. Inspect them periodically for wear and tear, and promptly address any issues to prevent potential safety hazards.

Ensuring Safety Measures

While these hooks enhance operational efficiency, it’s essential to prioritize safety at all times. Provide proper training to forklift operators on the correct use of quick release mounting hooks, and emphasize the importance of adhering to safety protocols and guidelines.

Environmental Impact

In an increasingly eco-conscious world, it’s worth considering the environmental impact of equipment and tools used in industrial operations. Look for eco-friendly options and practices, such as recycling materials and minimizing energy consumption, to reduce the ecological footprint of your operations involving forklift quick release mounting hooks.

Future Innovations

As technology continues to advance, we can expect further innovations in the design and functionality of forklift quick release mounting hooks. From enhanced automation features to eco-friendly materials, the future holds exciting possibilities for optimizing material handling processes in various industries.

Conclusion

In conclusion, forklift quick release mounting hooks are indispensable tools that streamline material handling operations, enhance efficiency, and promote safety across various industries. By understanding their functionality, benefits, and applications, businesses can harness their full potential to drive productivity and innovation in the workplace.

FAQs (Frequently Asked Questions)

1. Can forklift quick release mounting hooks be retrofitted to existing forklifts? Yes, many models are designed to be compatible with a wide range of forklifts, allowing for easy retrofitting without extensive modifications.

2. Are there weight limitations for the loads that can be handled with these hooks? Most forklift quick release mounting hooks are engineered to support significant loads, but it’s essential to adhere to manufacturer guidelines and recommendations regarding weight capacity.

3. Do these hooks require special training for operators? While familiarity with the equipment is necessary, the operation of forklift quick release mounting hooks is generally straightforward and intuitive. However, proper training on safety protocols and procedures is crucial to prevent accidents.

4. How often should maintenance be performed on these hooks? Regular maintenance should be conducted according to the manufacturer’s recommendations and based on usage frequency and operating conditions. Inspections should also be carried out before each use to ensure optimal performance and safety.

5. Can forklift quick release mounting hooks be used in outdoor environments? Yes, many models are designed to withstand various environmental conditions, including outdoor use. However, factors such as exposure to moisture, extreme temperatures, and corrosive substances should be considered when selecting and using these hooks outdoors.